Take a walk behind the scenes at KAON and you'll find an array of printed prototypes and profiles scattered everywhere; on the teams' desks, stacked on office shelves, and even on display in our little showroom.

But if you look more closely throughout our office, workshop and warehouse, you’ll spot 3D printed solutions everywhere. Pen holders, display stands, soap dishes, and coffee levellers for the espresso machine. And it's not uncommon to find the team swapping pictures of nifty parts and toys they’ve created at home, using their printers on weekends.

It’s safe to say that creating solutions to problems is a part of our DNA and that 3D printing plays a huge role in developing them. So, we thought we’d take you through why we love using it as a tool in our process, and how you can use it at home.

And perhaps the bit you’ll like most: we’ve gathered some handy KAON additions for your setup, that you can print at home.

.jpg)

Day-to-day, 3D printing enables us to produce our own components, and they can be spotted everywhere in our range.

You’ll find printed washers on our Cargo Barrier brackets to stop rattles; or on our Out-Back Gas Bottle Mount, where they keep our thumb screws secure on rough roads. We print retainers for clever cable management on our Camera Relocation Brackets, and our Rear Door Tables use printed bungee buttons.

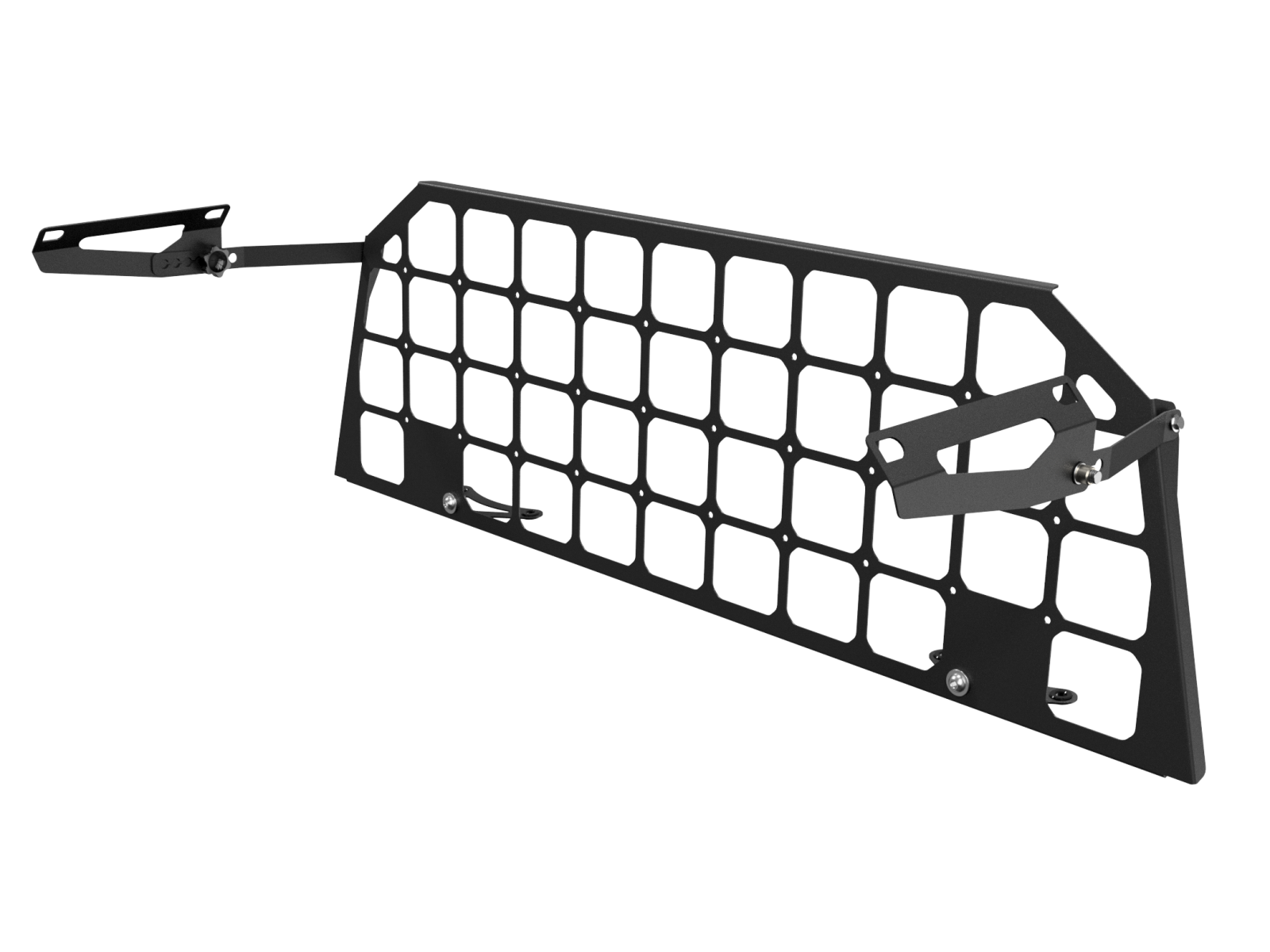

During product development, we use 3D printing for rapid prototyping: designing, manufacturing and testing at a speed the previous generation only dreamt of. In cases like our Recovery Points – which are ultimately CNC machined – it enables us to confirm and adjust fitment to suit a variety of vehicle configurations, so we can create a product that works for more people. As an integral tool in our design refinement process, 3D printing allows us to bring better products to market, faster.

.jpg)

.jpg)

.jpg)

As a DIY home user, printers are now more accessible and affordable than ever, with low-cost options coming in at just a couple of hundred dollars. There are also loads of educational resources available online, to help you learn the basics. Not to mention they’re an awesome way to get the kids interested in a hands-on creative and educational activity.

They’re also a surprisingly sustainable solution to creating components. Additive manufacturing is inherently a lower-waste, more sustainable process – that is, the production of a component by building layers, vs cutting away from a block of material. That’s before you throw in that 3D printing for yourself reduces the carbon footprint of delivered goods, and you can often use recycled filaments made from waste plastics.

Which leads us to the fun part...

With all this in mind, we decided it was time we brought you guys along for the 3D-printed ride.

We’ve gathered a selection of our printed designs, so you can enjoy printing your own KAON bits and pieces. With time, we’ll also add more designs, and even spare parts, so your gear continues to perform for years to come.

You'll find the projects below on GrabCAD, a free online community where creators of all skill levels share their designs.

Our legal team have told us we need to mention that these designs are for personal consumer use only, and commercial reproduction on any scale or for any use is not permitted.

So without further ado, let’s get printing!

Our Chopping Board clips allow you to store your cutting board securely in the back of your KAON Rear Door Table. The 3D-printed retaining clips lock the board into place and stay rattle-free. They’re also easy to install and remove; simply position the clips and push down on the board.

The settings you’ll need to complete this project:

You’ll also need:

We have two clip types:

360mm Deep to suit KAON Rear Door Tables for the:

350mm Deep to suit KAON Rean Door Tables for the:

You can find the files and print settings for our Chopping Board Clips here.

Don’t have a 3D printer? We also sell these in our store. You can buy the clips on their own, or we’ve even got an option with the board too – for those who prefer to save time (and avoid the IKEA maze).

.jpg)

.jpg)

Based on the design of our LC200 Recovery Tow Points, we designed this KAON Carabiner as a giveaway item for kids who stopped by our stand at the Expo... but it turns out our team loves them too. The workshop guys use them to clip cleaning rags on their pants, and many of the team have them hanging from their bags and keys.

The settings you’ll need to complete this project:

Latch file has a brim included to aid bed adhesion.

You can find the files and print settings for our Carabiner here.

.jpg)

KAON Dust Cap to suit ARB Compressors

No one likes dust or dirt in their air hose fittings, so we designed our dust cap to protect single and twin ARB compressor outlets.

The settings you’ll need to complete this project:

You can find the files and print settings for our Dust Caps here.

Note that 3D printing is not airtight, so we don’t recommend this for systems running air lockers.

We produce CNC machined, Anodised Aluminium Dust Caps for a more robust, hardwearing and long-term solution, especially for engine-bay mounted compressors. You can find these here.

We do still sell these as a 3D printed option, which you can find in our store here.

.jpg)

This one sits under the category of spare parts. For those of you who have one of our Light Cargo Barriers to suit a 5-Seat Pajero, you’ll have received this spacer as part of your kit.

The settings you’ll need to complete this project:

You can find the files and print settings for our 5-Seat Spacer here.

Share your creations by tagging us on Instagram or Facebook.

Whether it's one of our prints, something that complements our gear or a nifty project you've designed yourself – we're always keen to see what our customers are making.

Happy Printing!

Found yourself off-track? Our team is on hand to help you get unstuck.