We want to help change that. Recoveries are part of life off-road, and we believe knowledge is power, especially when heading off the beaten track.

Most know the basics. These pieces together as a system are often referred to as a 'Recovery Train':

1. You need a strap or rope of some form. Options vary widely, with Snatch Straps or Kinetic Ropes, and a wide range of length and stretch options. It is recommended that the minimum breaking strength should be between 2-3 times the gross vehicle mass (GVM) of the lightest vehicle in a recovery situation.

Most people carry a 9-10m strap, rated to 8t, with around 20-30% stretch.

2. You'll need a shackle to attach the strap. There are two common choices: a soft shackle or a hard bow shackle.

Nowadays, many prefer soft shackles, generally rated to around 14t.

3. And last but not least: a sound attachment point on both vehicles. This might take the form of a Recovery Hitch in the rear or a vehicle-specific Recovery Point at the front.

Generally, these should have a WLL (Working Load Limit) of at least 5t.

It's worth noting that a towbar is only tested to 1.5 times the towing capacity. A standard 50mm tow ball and tow bar at 3.5t is load tested to only 5.25t.

In most recovery situations, get these things right, and you'll be fine. But many don't fully understand how slightly tweaking just one or two factors can drastically alter the forces and loads at play and, consequently, the recovery outcome.

So what factors are most commonly responsible for recoveries gone wrong, and what can you do to mitigate them safely?

Armed with this question, our team set to work, investigating theoretical loads in recovery situations and just how quickly the forces at play can change.

If you're interested in geeking out with us, read on.

Here are a few terms you’ll need to know, so we’re on the same page.

MBS (Minimum Breaking Strength)

MBS is the load a piece of equipment can withstand before breaking in ideal conditions.

WLL (Working Load Limit)

WLL refers to the force that can be applied to a piece of equipment without fear of breaking and includes a margin of safety, often to a factor of 2-8 times.

GVM (Gross Vehicle Mass)

GVM is the maximum your vehicle can weigh when fully loaded, as specified by the manufacturer.

GCM (Gross Combined Mass)

It's also worth considering GCM, which is the maximum weight for your vehicle and trailer combined, as specified by the tow vehicle's manufacturer. GCM comes into play when recovering a vehicle towing a camper, boat or similar.

Coefficient of Friction

The coefficient of friction is the measure of the amount of interaction between two surfaces, as the ratio between friction force and normal force, or the force holding the two surfaces together.

When shopping for recovery gear, you'll find an array of terms used to rate their use. Due to the risks and consequences of a failure, these components are designed with safety factors and recommended working loads. However, how these safety factors are applied to various parts of the recovery train differ.

For instance:

This is where understanding the difference between MBS and WLL is important. A strap rated to an MBS of 8t will likely break at 8t. Whereas the WLL rating on a shackle includes a large safety margin, withstanding loads generally between 2-6 times the rated capacity.

These safety margins account for factors such as wear and tear, material and manufacturing variations, load arrangements, and risk and consequences of failure.

It's easy to understand why people can have difficulty comprehending what they need to allow for with recovery gear. The best way to work it out is to get an idea of what loads we can really expect. Beyond the total weight of our vehicles, how can we understand the actual loads being transferred through the recovery train?

Setting the Scene

The loads expected during a slow winch recovery are quite different to a more explosive snatch recovery. This is why most recovery incidents involving damage or injury can be attributed to snatch recoveries. To better understand why a recovery scenario goes wrong, we need to understand the size of the loads and how they are affected by how the recovery is performed.

So with that in mind, let's look at what happens during a simple snatch recovery.

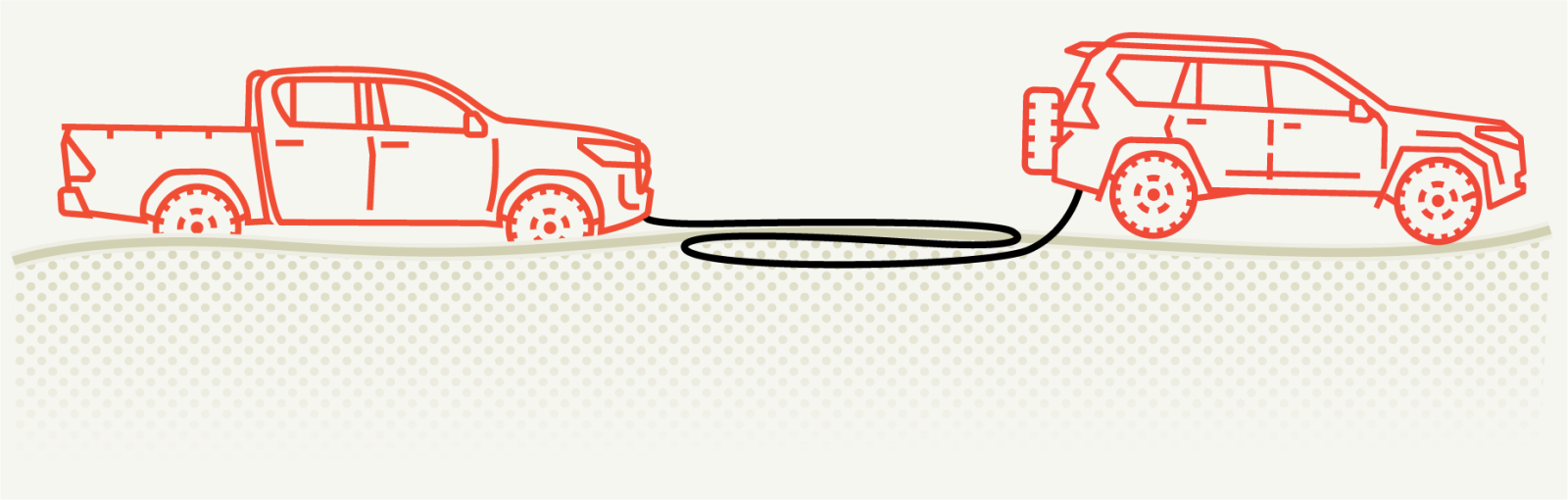

A stuck vehicle is attached to another vehicle performing the recovery.

The recovery vehicle is positioned ahead with some slack in the snatch strap.

Once the recovery vehicle begins the recovery, there is a point at which the snatch strap will start taking up load, stretching and slowing down the recovery vehicle. The run-up distance and acceleration of the recovery vehicle will determine its speed at this point.

If the stuck vehicle remains stuck after the kinetic energy is absorbed, the recovery vehicle can still apply a static driving force to the tow vehicle.

To understand the peak force possible in a recovery like this, there are two separate forces at play that we need to understand. These are:

First things first, let's calculate the driving force. It can be estimated based on the recovery vehicle's total mass, as well as the coefficient of friction of the surface the vehicle is driving on.

Simply put, we take the GVM and apply a friction multiplier, which is essentially traction.

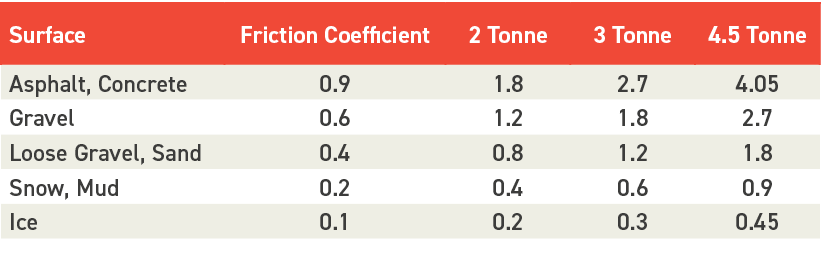

In the table below, our stuck vehicle has enough torque and power to spin all four wheels. You'll see that with more traction, the vehicle can generate forces almost equivalent to its mass. Situations that require a recovery, such as sand and mud, will have a much lower pulling force due to the reduced friction.

Friction Coefficient of Driving Surfaces

Understanding the Second: Calculating Deceleration Force

The stretch in the strap controls the amount of deceleration, and this is easy to picture: a strap with no stretch will create instant deceleration, transferring a very abrupt, large force.

We can calculate this deceleration force using Newton’s formula: Force = Mass x Acceleration. To do this, we need to understand two things:

To be confident that the actual loads are within our calculated loads, we’ll make a few assumptions based on a typical recovery. These are:

With these baseline assumptions established, we can now use high school physics and math to calculate velocity and acceleration. We need to calculate the maximum speed the recovery vehicle will achieve before the snatch strap takes up the load and begins to decelerate the recovery vehicle.

.png)

What Factors Make the Biggest Difference

With all this in mind, we can now look at how the forces at play change with different variables, that is, where recoveries often go wrong.

The Recovery Vehicle’s Mass

Mass is directly proportional to the force generated due to deceleration. A 4.5t vehicle will generate 50% more force than a 3t vehicle, provided it can accelerate up to the same speed.

This is why we base recovery strap selection on the lighter vehicle. Straps rated to a higher weight are stiffer and require more force to stretch. A correctly selected strap will stretch more than an overrated strap, resulting in a gentler and safer recovery with lower deceleration force.

Selecting an underrated strap means that you are more likely to approach the MBS of the strap, especially if there is any aging or degradation to the strap. Conversely, an overrated strap is more likely to overload and break the shackles or recovery point – a dangerous situation.

The Run-Up Distance

The run-up distance depends on the length of the recovery strap and the position of the vehicles.

If the two vehicles in the recovery are 6m apart and attached with a 9m snatch strap, the run-up distance is 3m. The maximum run-up distance would be 9m, or more with the use of a bridle and joined straps.

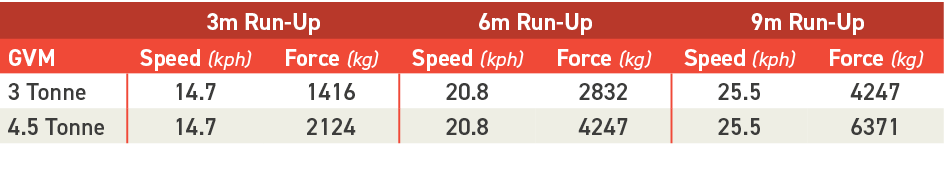

Velocity and Deceleration Forces based on Run-Up*

*Assuming 9m snatch strap with 20% stretch. 0-100 in 10s acceleration.

We see here that speed depends on acceleration distance; therefore, the force generated is directly proportional to the run-up distance. A 6m run-up distance will generate twice the force of a 3m run-up.

Simply put, more distance allows more speed, which means higher forces.

The Stretch of Your Snatch Strap or Kinetic Rope

Now let's look at a factor many may not consider: how the amount of stretch in the snatch strap or kinetic rope affects the loads.

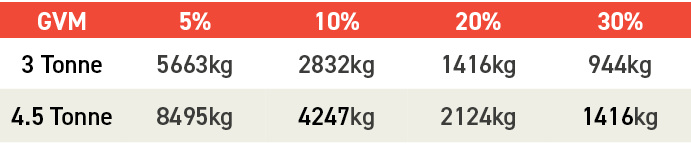

Velocity and Deceleration Forces based on Stretch*

*Assuming 9m snatch strap with a 3m run-up. 0-100 in 10s acceleration.

We can see here that the amount of stretch in a snatch strap can significantly reduce the maximum force transferred through the strap. Note how the reduction of stretch from 20% to 10% doubles the loads.

There are other factors to bear in mind too. Straps need time to recover their stretch between loading, and they also lose their properties over time – meaning it pays to ensure your kit is well looked after.

Essentially, more stretch means a greater distance to decelerate over, which means less load.

Putting it All Together in a Real-World Scenario

You will have noticed that some of these numbers we've found so far exceed the ratings on standard recovery gear. The best way to work out what we can expect in the real world is to explore a typical snatch strap recovery, so let's throw some values at the scenario we discussed earlier.

The Driving Force:

Sand Recoveries are a typical case for a snatch recovery.

We know that sand has a friction coefficient of 0.4.

The stuck vehicle would usually be bogged to at least the rims, corresponding to a resistance load equal to the GVM.

Most vehicles sit at around 3t. So, let’s say we have a 3t stuck vehicle and a 3t recovery vehicle.

The Deceleration Force:

We’ve got a typical snatch strap, at 9m long and 20% stretch, with a minimum breaking strain of 8t.

Using best practice recovery techniques: the recovery vehicle would have a 3m run up and get to a maximum speed of 15km/h, assuming the vehicle is capable of 0-100km/h in 10s.

This would result in a deceleration force of 1416kg and stretch the strap 1.8m.

If the recovery vehicle continues to apply power after it comes to rest, the tractive forces due to friction would add another 1200kg, assuming the friction is 0.4 with sand.

The Outcome:

This recovery could generate a theoretical total force of 2616kg, well within the rated capacity of standard recovery gear.

How this Scenario Could Go Wrong

So, how can it go wrong? Let’s take nearly the same scenario and see how tweaking a few of the circumstances in a recovery can radically affect the outcome.

The Driving Force:

Again, let’s use a sand recovery.

The stuck vehicle is still bogged to at least the rims, corresponding to a resistance load equal to the GVM.

We have the same 3t stuck vehicle, but in this scenario, we’ll say our recovery vehicle is overloaded or has an above-average GVM, at 4.5t.

The Deceleration Force:

We’ve got the same snatch strap, at 9m long and 20% stretch, with a minimum breaking strain of 8t.

But in this scenario, instead of using best practice recovery techniques with an S-bend and 3m run up, let's start the vehicles bumper-to-bumper with a 9m run up. With a maximum speed of 25.5km/h, assuming the vehicle is capable of 0-100km/h in 10s.

This would result in a deceleration force of 6371kg and stretch the strap 1.8m.

If the recovery vehicle continues to apply power after it comes to rest, the tractive forces due to friction would add another 1800kg, assuming the friction is 0.4 with sand.

The Outcome:

This recovery could generate a theoretical total force of 8171kg, well over the rated capacity of standard recovery gear.

We can ascertain from this that we could break a strap, and whilst it is still within the safety factors of the recovery points and the shackles, it's well above common WLL ratings.

A more enthusiastic second attempt with less stretch could potentially double this load again, easily soaring over 12,000kg.

You’ll see it only takes a few factors – a heavier vehicle, and poorer technique – for the loads to climb above recommended limits. This is when we see failures occur. At this end of the scale, you’re potentially going to break the strap, or even your recovery point.

What We Can Learn From This

At its core, we can see that increasing forces in a recovery comes down to three main things: more mass, more speed and less stretch. Friction and tractive driving force from the vehicle are also contributing factors we should not overlook.

It’s good to understand what conditions can cause loads to exceed the rated capacity or breaking strain of your recovery gear. Things like reduced stretch due to multiple attempts or a large run-up could see loads total loads over 10t. Understanding these factors also helps us know how to significantly reduce peak loads in the recovery train, particularly through snatch straps that provide more stretch. Not to mention reducing the speed of recovery, proving that, where possible, a slower, steadier recovery is best.

In recoveries-gone-wrong, you’re most likely to see a strap break, or worse: a recovery point. It’s bad enough to have a snatch strap break, but it's actually the least dangerous situation. Break a recovery point, and you have not only a strap flying through the air, but a shackle and a recovery point too.

This is why it's crucial to have a recovery point with an adequate rating for your vehicle. If your point has a WLL of just 3.5t, and has been tested to a safety factor of 2, there is the chance that your recovery point could break with a mere 7t of force. We’ve seen already that it doesn’t take much to exceed that.

But perhaps the most important takeaway from this exercise: it’s good to know if you take a little time to select appropriately rated gear for your vehicle and use it correctly in a typical situation, you’ll be just fine.

Found yourself off-track? Our team is on hand to help you get unstuck.